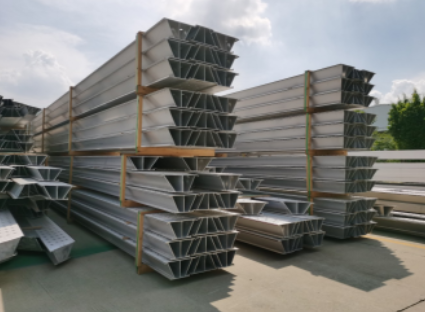

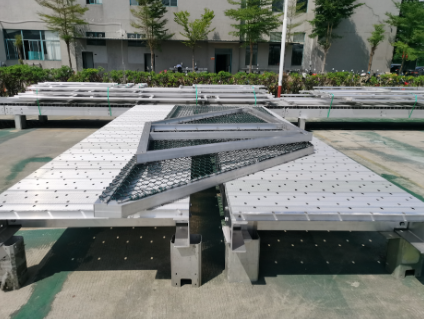

WHY ALUMINUM

Aluminum is the metal of choice for leading designers, architects and engineers, who want a material that combines functionality and cost effectiveness with innovative form and design potential.

Given the unique properties of aluminum, these allow architects and designers opportunity to push the limits of design. Reducing weight without comprise to safety, strength, integrity and durability.

PMI has extensive experience and in house R&D to support our clients to overcome the most difficult of design challenges, by working in collaboration to produce a technically compliant custom solution.

We appreciate that a considerable amount front end development goes into the scoping and design of the required extrusion prior to sending to your extruder for further determination.

However from our experience and observations there are a few more factors to pay attention to that will reduce cost and lead time on the qualification of the design.

We’ve taken some time to identify our top three (3) more common design issues that we believe if addressed and the front end can assist designers in avoiding design delays. When Form and function

1, DESIGN BRIEF (SCOPE OF WORK)

If you were to receive a drawing for a part with little information on it other than the grade and part, would you be confident that the alloy indicated was appropriate for the application? Could you accurately assess that the profile would withstands required stresses if not knowing how is going be used. Designers often fail to share full product details with their aluminum extrusion manufacturer such as whether a component will only bear weight or exposure to heat among other things; these are critical in determining proper alloys & tempering needed.

A drawing accompanied with a clear concise design brief provides invaluable information to the extruder. which could have a beneficial impact on suitability, optimization & reliability.

2, DIMENSIONING & TOLERANCES

As a designer, you want to design a new aluminum extruded component that fits well and functions properly. You also want to minimize cost by avoiding unnecessary tight tolerances.

The most common option for setting up tolerances is by using the corporate standards set within the title block. This is usually fine, however in the design of highly precise, extruded parts this can lead to poor fit or function in the finished part due which could lead time unforeseen rework or inaccurate assumptions about how the part will be built.

Spending time properly dimensioning and applying the appropriate tolerances in important zones in the design can help you create a profile with tighter tolerance will helps avoid costly mistakes in your die or profile manufacture, while still allowing room for manufacturing flexibility.

Be consistent in the tolerance method, equally as important is consistency in dimensioning. Avoid text edit shortcuts, these are hard to identify and will cause costly delays in the extrusion development.

3, RADIUS CORNERS & WALL THICKNESS

How do you make aluminum corners stronger and easier to extrude?

The problem with sharp edges is that they are more likely to chip, crack or break during the extrusion process. Sharp edges also cause a lot of friction in the die which can lead to other problems like warping or jamming.

Radius corners are much stronger and allow the hot aluminum to flow easier through the die which in turn is easier to extrude than sharp ones. Rounded corners don’t have any hard angles so there’s less chance for chips, cracks or breaks when being forced through an opening in the die.

Rounded corners also create less friction so there’s less chance of jamming or warping inside of a die. Most rounded corner designs can be made from 0.2mm radii (0.1-0-5) up to 1mm radii (8-25).

Make sure the wall thicknesses in your design are uniform to avoid any problems with extrudability. If possible, try and maintain a thicker dimension for longer periods of time without switching sides or having sharp transitions where there should be rounded edges; this will also ensure that anodizing techniques work more efficiently across different surfaces.

PMI has extensive experience in custom aluminum extrusion and are committed to supporting you clients becoming a strategic partner at the front end of your next project to support your R&D requirements. PMI can support your most difficult challenges so please do not hesitate to contact us to find out more about how we can help you.